Firefighting Systems

Fire extinguishing systems in their simple version consist of main electric or diesel pumps and an electric jockey pump. They include control panel, pressure regulators, suction and discharge manifold, isolation valves for each pump, check valves and pressure vessel as required. Upon request, fire extinguishing assemblies are available, in accordance with European standards and with high quality.

- Available on a single basis or individually as required.

- Can be delivered and installed in sections in pumping stations with limited space or difficult access.

- Possibility to install each electropump separately as well as the diesel.

- Possibility of construction with only electric pumps, in case of an electrically driven pair.

- Detailed information on the above assemblies is available upon specific request.

| ||||||||||||||||||

FIREFIGHTING ASSEMBLY IN ACCORDANCE WITH EUROPEAN STANDARD EN12845/EN 12259-12

The fire extinguishing assembly, according to EN12845/EN12259-12, consists of:

- Main electric pump

Electric pump, consists of horizontal centrifugal free axle pump and electric motor. The connection of the pump to the engine is made by means of a rubber connector with a renegade, in order to ensure the maintenance of the hydraulic part without disassembling the piping (back pull-out design). The electric motor is Blueflux technology which ensures IE2 energy consumption levels.

- Main Diesel Pump

Oil powered pump system, consists of horizontal free axle centrifugal pump and diesel engine. The diesel pumping assembly is supported by means of anti-vibration treads on a strongly constructed steel base. It is accompanied by a fuel tank and accumulators of unequal size. The connection of the pump with the engine is carried out via a rubber connector with a renegade in order to ensure the maintenance of the hydraulic section, without the back pull-out design. The diesel engine is of European construction, of appropriate nominal power.

- Auxiliary electric pump (Jockey)

Auxiliary electric pump assembly (jockey) consists of a stainless steel vertical, multistage, centrifugal pump and an electric motor. They are directly connected (monobloc). It is a sturdy construction , suitable for continuous operation. Sealing is achieved by means of a mechanical seal. The electric motor is Bluefl ux technology which ensures IE2 energy consumption levels.

- Automation tables

According to the new EN12845 standard, each engine of the assembly (electric motors and diesel engine) must be controlled by a separate automation panel.

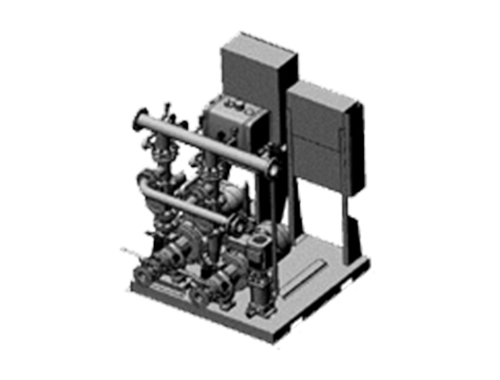

PEERLESS FIRE EXTINGUISHING SYSTEMS, IMPORTED IN ACCORDANCE WITH AMERICAN SPECIFICATIONS NFPA20 AND CERTIFIED BY UL/FM

The complexes are manufactured by the American company Peerless, a member company of the Grundfos Group, with 80 years of

experience in the manufacture of fire extinguishing systems.

The assemblies are ready for installation. The pump, the electric motor / diesel engine and the control panel are placed on a single base. The electrical connections are integrated. The fact that the complexes are delivered pre-assembled eliminates any complicated and costly problems installation. Both horizontal and vertical pump types can provide up to 5000 gpm. End-suction types provide up to 1500 gpm and in-line types up to 500 gpm. The pumps work with electric motors, diesel engines or steam turbines. All components and accessories of fire-fighting pumps have specifications NFPA 20.

HIGH STANDARD FIRE FIGHTING ASSEMBLIES

Each fire extinguishing system consists of the following:

Electric or diesel main pumps, electric jockey pump, pressure regulators, suction and discharge manifolds, pressure gauge, control panel, check valves, blocking valves.