This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Grundfos service center

Since 2000, “MECHANICAL ANTLIES” has retained the title of its authorized service center of GRUNDFOS. Additionally from 2017 and onwards, it has been additionally certified by the independent body of inspectors BUREAU VERITAS, on behalf of GRUNDFOS, in order to ensure the highest quality services to the end user.

The target was achieved after continuous intensive inspections in the following areas :

- Facilities and Staff

- Branding and Communication

- Environmental Policy

- Certification and Organization

- Safety & Hygiene

and an overall percentage of 89%

Service Process

By handling over 800 service cases a year, we have created a repair management system that is absolutely transparent and leaves no room for misjudgments or misunderstandings. We focus on the immediate and complete customer’s information by the moment we receive his machine and during the repair. We keep a record of repairs, photos of products and their damaged spare parts, while providing to the customer the option to watch every stage of the repair process, by attending our facilities.

The warranty we provide on each repair is 1 year and the terms are mentioned here.

Pump as purchased

We provide the possibility of full product reconstruction restoring it to its original condition and extending its life for additional years.

- Chemical cleaning of stainless steel and synthetic parts

- Cleaning of surfaces

- Polishing

- Painting

- Performance testing

Diagnosis / problem solving

The Service Engineers focus on the correct diagnosis, aiming to fully inform the final user and address the problem. For this reason, they often act in a supportive way. Initially they recommend and finally offer the necessary services or products in order to solve permanently the problems that cause damages or malfunctions in the customer’s pumping system.

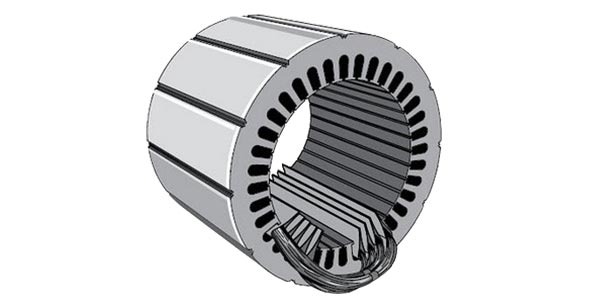

Surface electric motor winding

In our workshop we maintain a surface winding department for electric motors, serving the needs of our customers and ensuring that our repairs are handled exclusively by our company’s engineers. By implementing an ISO EN 9001:2015 quality assurance system, we ensure through our internal process that the product, upon completion of the winding, will be fully functional and will comply with current safety rules and standards.

Control procedure and testing:

- Insulation resistance check with calibrated instruments

- Test under load up to 63 A

- Off-load test up to 400KW

- Painting with electro-insulating impregnation varnish

- 1 year warranty

Winding of underwater electric motors

The winding department of our workshop is one of the first in the field specialized in winding submersible drilling motors with PVC or PE/PA wire. Ednuring experience of the staff as well as the excellent equipment ensure the desired result expected by the prospective customer. The implementation of the ISO EN 9001:2015 quality assurance system combined with the meticulous internal inspection and final testing process lead to the even result. That the product will be fully functional and comply with the applicable safety rules and standards

Control procedure and testing

- Continuous control of the wire throughout the winding process.

- Measurement of insulation resistance with calibrated instruments, inside the tank

- Test under load up to 63 A

- Off-load test up to 400KW

- PVC or PE/PA wire

- Supply cables certified for potable water

- 1 year repair warranty